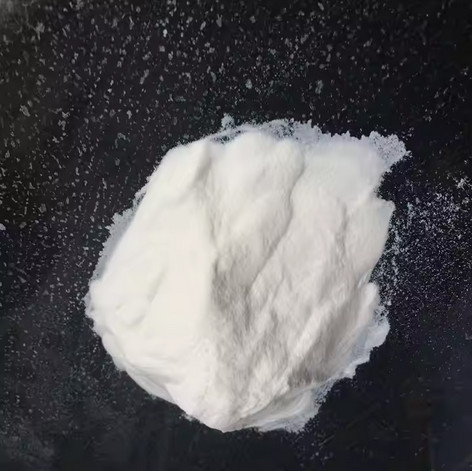

Nano-structure of Silica Anti-Caking Grade (ZEO12)

Silica nano-structure (ZEO12) acts as a very effective anti-caking agent

due to its suitable specific surface area and low specific weight, and gives very valuable properties

to polymer products. It also prevents the materials from sticking together and becoming lumpy.

This grade is produced synthetically under the name of amorphous silicon dioxide (SiO2).

Silica nano-structure (ZEO12) in the polymer industry, to prevent powder particles

from sticking together and facilitate the mixing and molding process, in polymer composites to

improve mechanical properties and increase wear resistance, and in engineering plastics to increase

resistance thermal and chemical are used.

Role of Nano Silica as an Anti-Caking Agent in the Polymer Industry (ZEO12)

Anti-caking refers to substances that prevent particles of a material from sticking together and forming clumps. In the polymer industry, nano-structured of silica acts as a very effective anti-caking agent, imparting valuable properties to polymer products.

Role of Nano Silica as an Anti-Caking Agent including

- Creating a Protective Layer: Nano silica particles create a thin layer on the surface of polymer particles, preventing direct contact between them.

- Reducing Adhesive Forces: This thin layer reduces the adhesive forces between particles and prevents clump formation.

- Increasing Flowability: Nano silica increases the flowability of polymer powders, making mixing and molding processes easier.