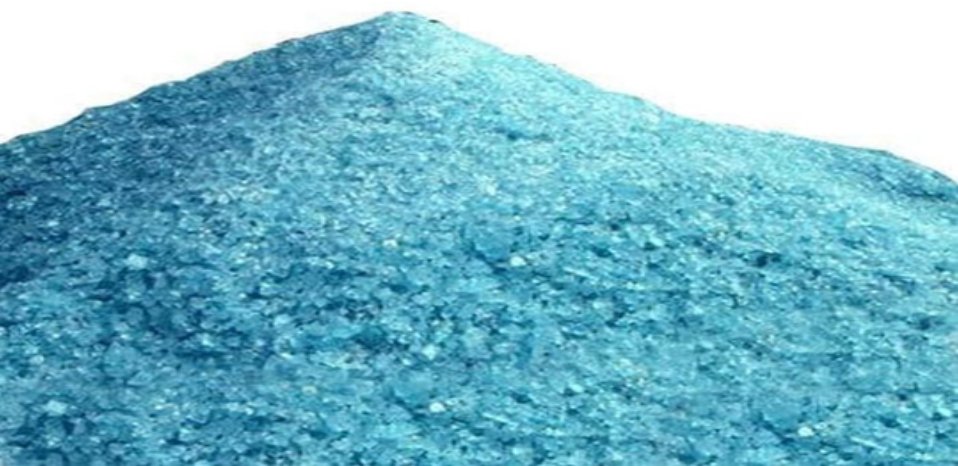

Sodium silicate, also known as water glass, is a versatile inorganic chemical compound that finds applications in various industries due to its unique properties. It is formed by combining sodium oxide (Na2O) and silicon dioxide (SiO2) in an aqueous solution, resulting in a range of products with different compositions and properties. In this article, we will delve into the production process of sodium silicate and explore its diverse applications.

Production of Sodium Silicate: Sodium silicate is produced through the reaction of sodium carbonate (Na2CO3) and silicon dioxide in the form of silica (SiO2). The reaction takes place in a high-temperature furnace, typically at a temperature of around 1200°C. The chemical equation for the production of sodium silicate can be represented as follows:

Na2CO3 + SiO2 → Na2SiO3 + CO2

This reaction results in the formation of sodium silicate and carbon dioxide gas. The sodium silicate produced is typically in a liquid form, which can be further processed or used directly in various applications.

The ratio of sodium carbonate to silicon dioxide used in the reaction determines the properties of the sodium silicate product. Higher ratios of sodium carbonate result in a higher concentration of sodium oxide in the final product, leading to an alkaline solution. Lower ratios, on the other hand, produce a more acidic sodium silicate solution.

Applications of Sodium Silicate: Sodium silicate has a wide range of applications across multiple industries due to its unique chemical and physical properties. Some of the key applications are outlined below:

- Adhesives and Binders: Sodium silicate is commonly used as an adhesive and binder in various industries. It is particularly valued for its ability to form strong bonds between different materials, including metals, glass, wood, and concrete. Sodium silicate-based adhesives find applications in paperboard and corrugated cardboard manufacturing, as well as in the production of fire-resistant materials.

- Detergents and Cleaning Products: In the detergent industry, sodium silicate serves as a crucial ingredient, providing alkalinity and corrosion resistance. It acts as a detergent builder, helping to remove dirt and stains from fabrics by enhancing the cleaning efficiency of surfactants. Sodium silicate also finds use in automatic dishwashing detergents, laundry detergents, and industrial cleaners.

- Water Treatment: Sodium silicate is employed in water treatment processes to control corrosion and scale formation. Its alkaline nature helps to stabilize pH levels in water, preventing the formation of acidic conditions that can lead to corrosion. Additionally, sodium silicate is used for coagulation and flocculation processes in wastewater treatment, aiding in the removal of impurities and suspended particles.

- Construction and Cementitious Applications: In the construction industry, sodium silicate finds use as an ingredient in cementitious products. It can act as a binding agent in the production of refractory materials, including fire bricks and high-temperature insulation. Sodium silicate is also used as a concrete sealer, providing water resistance and increased durability.

- Automotive and Metal Treatment: Sodium silicate is employed in automotive applications, such as foundry operations and the production of automotive parts. It serves as a core binder in the foundry industry, facilitating the molding and casting of metal components. Sodium silicate is also utilized as a corrosion inhibitor and coating material for metal surfaces, protecting them from oxidation and rust.

- Textile and Fiber Industry: In the textile and fiber industry, sodium silicate is utilized as a flame retardant. When applied to fabrics, it forms a protective layer that reduces flammability. Sodium silicate also enhances the dyeability and color fastness of textiles, making them more resistant to fading and improving their overall quality.

- Paper and Cardboard Manufacturing: Sodium silicate plays a vital role in the production of paper and cardboard. It acts as a sizing agent, providing increased strength and water resistance to paper products. Sodium silicate is also used as a coating material for cardboard, enhancing its durability and preventing moisture absorption.

- Agricultural and Soil Stabilization: In agriculture, sodium silicate is utilized as a soil stabilizer and conditioner. It helps to improve soil structure, reduce erosion, and enhance the water-holding capacity of the soil. Sodium silicate can also be used as a foliar spray to protect plants from fungal infections and pests.

- Specialty Applications: Sodium silicate finds applications in various specialty areas. It is used in the manufacturing of catalysts, particularly for biodiesel production and petrochemical processes. Sodium silicate is also employed in the production of silica gel, which has moisture-absorbing properties and finds use in packaging, drying agents, and humidity control.

- Safety Considerations: While sodium silicate is generally considered safe for many applications, it is important to handle it with care. It is alkaline in nature and can cause skin and eye irritation. Protective measures, such as gloves and goggles, should be used when working with sodium silicate solutions.

Conclusion: Sodium silicate, with its wide range of applications, is a versatile and valuable chemical compound. From adhesives and detergents to construction materials and water treatment, its properties contribute to the performance and functionality of various products across multiple industries. The production of sodium silicate involves the reaction between sodium carbonate and silicon dioxide, resulting in a liquid solution that can be tailored to meet specific requirements. As industries continue to innovate and seek sustainable solutions, sodium silicate’s role in enhancing product performance and meeting environmental challenges is likely to expand.